Production

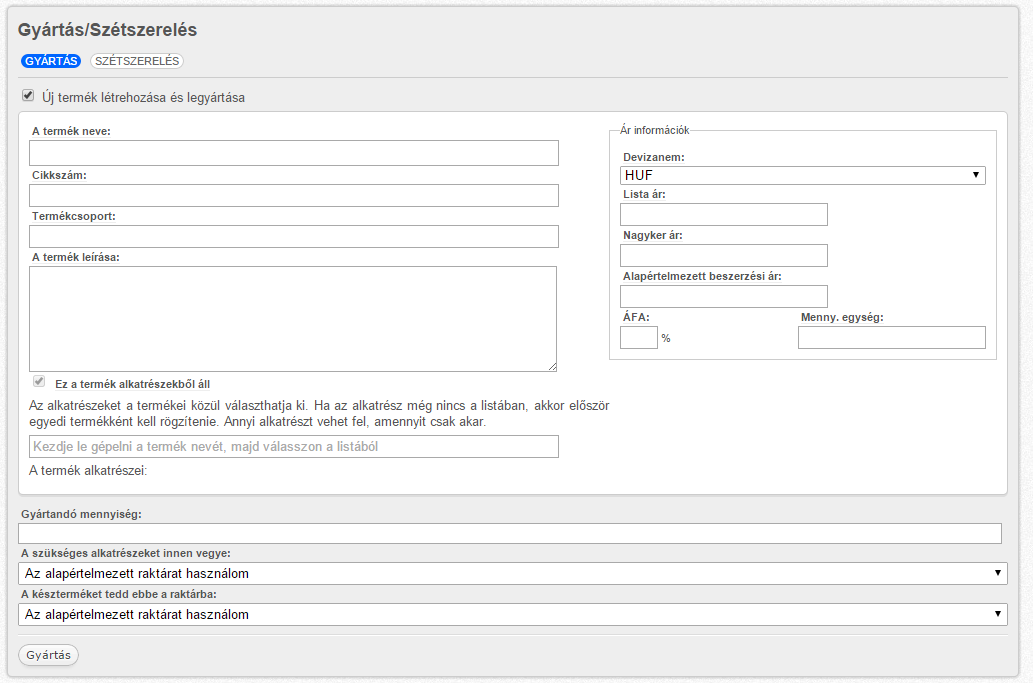

In the “Products & stock” module’s “Production/disassembly” select the “Production” button. After selecting it, you can choose from products consisting of parts or products which don’t have parts. After selecting the desired product, you must give how many of that product you want to produce. The system takes the parts from the given warehouses, but it can also be define to take the parts from any warehouse according to the FiFo principles. The produced product will land in the desired warehouse.

During production it is also possible to create a new product by selecting the "Create and manufacture a new product" option “Create a new product then do the production” box. A simplified product registration form will appear, which you can fill out to create a new product to be produced.

It is also possible, to add a part to a product which has no parts. In this case, you need to select a non-part product and then add the products.

After completing the form, press the “Assembly” button. The system will check if there are enough parts in the selected warehouse(s) - all warehouses are checked if you choose “any warehouse. If there are not enough parts, the system will alert you and will also notify you about how many products can be assembled now.

The assembled product will be moved to the selected warehouse. The following changes are made in stock:

- The assembled product will be moved to the selected warehouse. The product's price will be the sum of all the parts used during assembly.

- The used up parts will be moved out of the warehouse that they were in.

A receipt can be made about these product changes.